Different types of steel sheets are available in the market, and oiled sheets are more efficient than hard sheets.

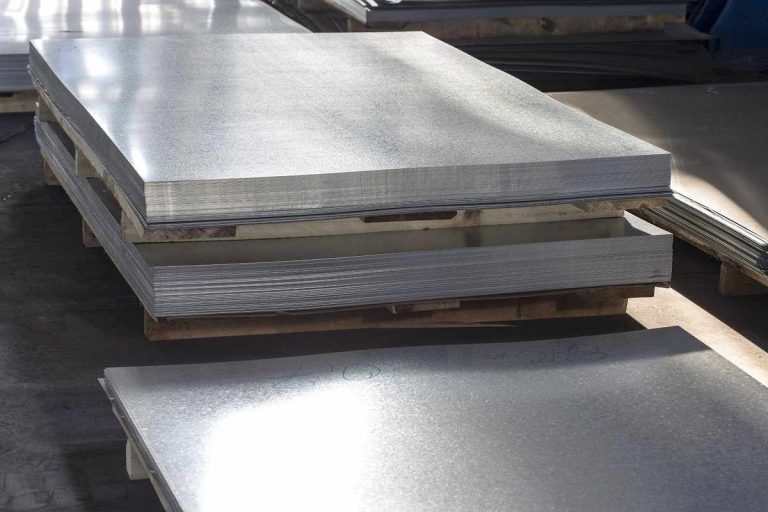

Different steel sheets available in the market Depending on their application, steel mills around the world produce different types of steel sheets.

The production method is the main difference between these sheets, and some are used as raw materials for other sheets.

Steel plates include the following: tin plate or tin plate acid wash plate cold plate or oil plate hot plate or black plate painted plate galvanized plate or white plate Tin plate is resistant to moisture.

Sheet tin or coated tin is very similar to galvanized sheet, which is the basic material of both steels, the difference is that galvanized sheet has a zinc coating, but tin sheet is covered with tin metal.

The presence of tin coating on the steel sheet changes the wear time of the product and makes it resistant to oxidation, which makes coated tin plates a suitable product for humid environments exposed to water and rain.

Tin gauge is used in industries such as canning industry, automobile manufacturing, making household and kitchen appliances and electrical equipment, and in the construction industry for fencing, roofing and covering special places.

The transparent and polished pickling paper is like oil paper. Pickling board is one of the boards that is used in all walks of life and it is made of blackboard.

It can be said that the production process of pickled board is very similar to cold board in some stages. Pickled board has popular applications in industries where job appearance is very important.

Automotive, construction and other industries. Blackboard is the primary material for the production of pickled boards.

In the production process, the surface of the blackboard is first washed with acid to remove some of the grease and impurities. This makes the sheet more transparent and the final product is very similar to the cold sheet.

Pickled sheets are usually 1.5 to 6 mm thick. Dark and cloudy blackboard sheets are produced in the hot rolling process.

The reason for naming this blackboard product is its cloudiness due to the melting of the steel plate during production, which is called blackboard.

The manufacturing method is that the manufactured metal sheet is placed at a very high temperature and after this, an oxide layer is formed on the metal sheet. Then this layer is washed, which reduces the temperature of the bed surface.

After this stage, the sheet goes to the rough stage and completes the steps of passing through the rolls to finally reach the desired size.

This process reduces the sheet thickness from 15% to 30%. There are 2 to 3 bases for rough rolling, after which the product enters the final rolling stage and finally becomes blackboard.

Standard oil sheets in the Iranian market are usually produced under the standard names ST14, ST12 and ST13 with different tensile strength. These sheets are usually between 12 and 28 in length.

Cold-rolled steel sheets or ST14, ST12 and ST13 steel sheets are used for tensioning, and all kinds of cold-rolled steel sheets are included, and the price of oil-coated steel sheets varies depending on the type.

ST12 paper is a more conventional quality paper. Their surfaces are completely smooth and without cracks and corrosion and are used in applications such as coating and shaping.

Being the same on both sides of this sheet and having the same properties are other features of ST12 standard sheet.

This sheet is known as a normal oil sheet in various markets and industries and has the ability to be welded. ST14 sheet is another standard oil sheet with high elasticity.

The production process of this type of sheet is such that the aluminum metal is oxidized during the production process and the surface is smoother and more polished than ST12 sheet.

The surface smoothness of this oil set depends on the customer’s order. ST13 sheet is another standard oil sheet on the market with properties between ST12 and ST14. It has moderate elasticity and is mainly used when more shaping is needed.

In addition to the three sheets mentioned above, there is also an oil-based sheet called EK2 sheet in the market.

This board has glazing features, so it can have a variety of colors and is mostly used in the production of kitchen appliances such as gas stoves.

After cold rolling, the steel sheet is coated with oil to become an oil plate, but the oil is easily washed off with alkaline solution during use.

ST is the abbreviation of the German word Standard Oil Boards, part of the German DIN. Standard names usually consist of symbols and numbers, such as Table ST14 and Table ST12.

ST is derived from the German word Stahl, meaning steel. The numbers used in oil paper standards also indicate the minimum tensile strength of the sheet.

Greater Efficiency of Oiled Sheet

After hot rolling, there are oxides and impurities on the surface of the sheet, and its size is not accurate enough. By rolling the surface at ambient temperature, the sheet has a high surface area, higher dimensional tolerance and higher strength.

The product of this process is called cold rolling and two types of annealed and fully hardened are available in the market.

At the end of the manufacturing process, the annealed sheet is used to protect the surface of the sheet from rusting again, and some oil is sprayed on the surface of the sheet to facilitate the subsequent production processes.

This is the reason why this type of sheet is also common in the Iranian market, such as petroleum sheet, which is generally more durable and efficient than full hard sheet. In some cases, full cardboard is used. Its properties are more effective as an input material for galvanized lines.

Oil foils for coils and sheets are available in the market and depending on the end application, determine the strength and elasticity of the coils.

It is important to note that the price of a product depends entirely on its features. The size, size, thickness, quality, etc. have a direct effect on the price of steel sheet and the price of oil sheet, so you should pay attention to the features you need before buying in order to buy a product with the right performance you need.

The oily sheet is the basis for the production of galvanized white sheets. One of the reasons for naming these tables is their appearance. This sheet is made with cold rolling technology and is one of the types of cold sheets. This process allows the sheet to be rolled from high thickness to low thickness.

Iron or steel surfaces must be thoroughly cleaned before galvanizing. The cleanliness of the surface makes the chemical reaction process of steel or iron rods to be carried out well.