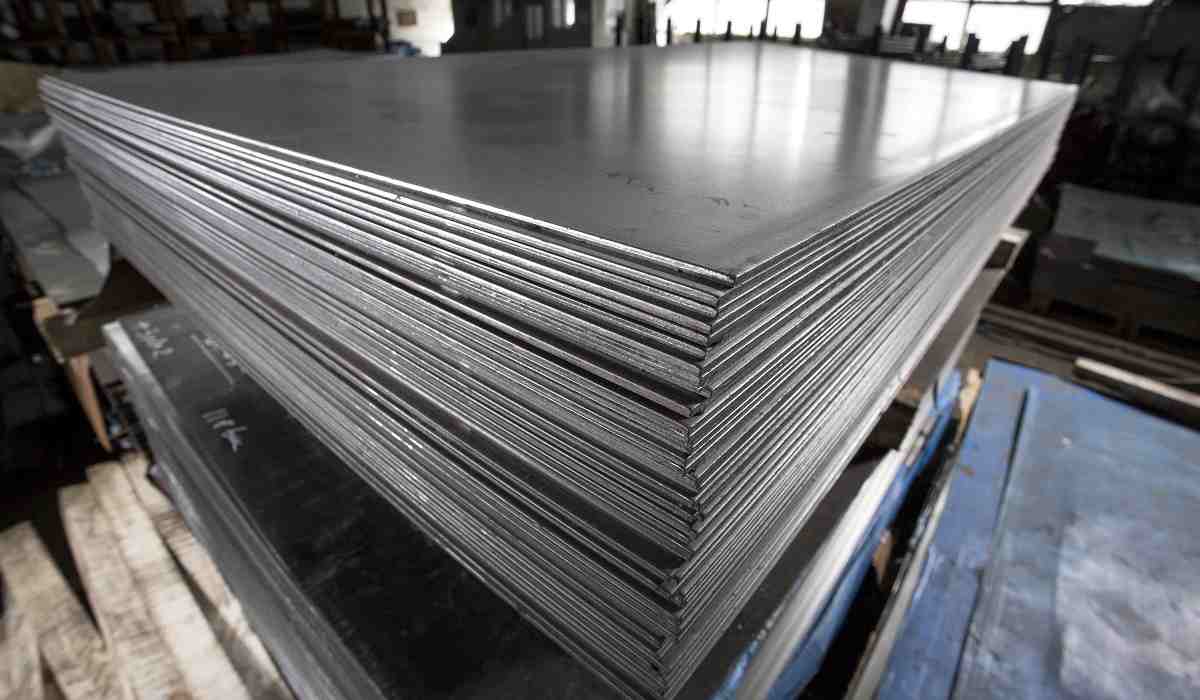

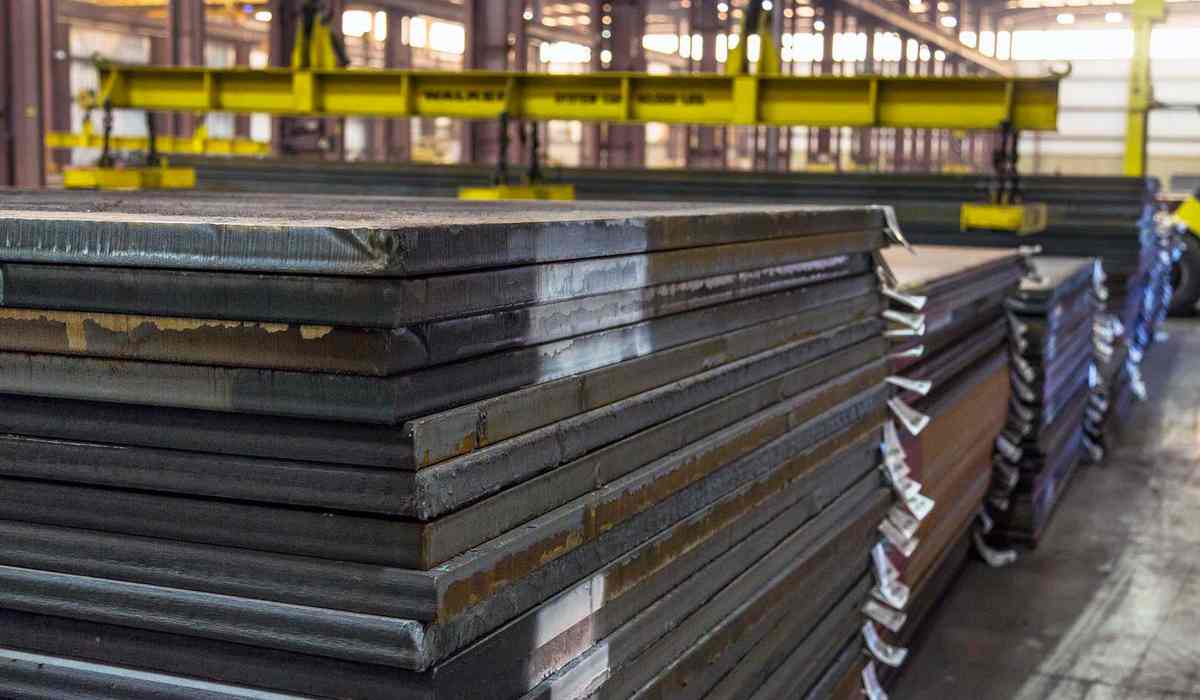

Steel sheet is a kind of metal sheet which has smooth surface, can be rolled and coiled and is the same shape as industry required. The steel plate is also known as the steel plate.

There are many different types of steel sheets, each of which is classified and named according to the manufacturing method used, and the raw materials in the composition of those sheets.

Black Sheet: The surface of this sheet is not smooth and polished, which is why it is known as black sheet. Their name has also been changed because of the lack of food and smoothness of language.

The hot rolling process has been used in the production of this kind of steel sheets. Use a rolling technique. In order to steel forming and obtaining the required thickness, rollers are used in this process.

These plates are used to manufacture a variety of products, including welded pipes, ships, profiles, and body.

Galvanized Steel Sheet(In White):

Welding is one of the most important processes that should be considered when making steel items. Besides, the use of stainless steel can be very expensive for some special kinds of business.

Therefore, it is necessary to find a solution to enable the production of steel plate at a lower cost. It was made as corrosion resistance as humans were imaginable. For this purpose, a galvanized coating is formed during the process of fabrication on stainless steel plates.

Oil-type steel plates are placed in a single cavity containing molten metal during the galvanized process. This is galvanized sheet production. And then Roy must be allowed to cover the top of the screen.

The sheet is strengthened more effectively, using more zinc to cover it. In addition, it has more corrosion resistance.

Additionally, galvanized sheet has a longer life and can normally continue to operate for up to 50 years. Even when exposed to high moisture content, they can work well for up to 20 years without the need for maintenance.

Galvanized sheet is used in several applications, including water pipes, cabinets, tanks and water storage tanks.

Oil sheet:

The glossy appearance of oil sheets is the source of their aliases, which do not exactly reflect their textures. Given to them. The use of cold rolling technique which leads to the production of sheet with a glossy surface is what is responsible for the production of this.

The goal of cold rolling method is to produce a high quality steel plate which is its nameplate. Create anything with a relatively thin layer.

The final results of this method is the product of hot rolling process output. After cooling, it passes the acid washing process and then the coil is rolled together. After that, he became familiar with the cold rolling process and the steel plate.

In order to obtain the desirable thickness for the sheet, it travels through the rollers at a lower temperature than before.

The production of galvanized sheets starts with these types of sheets as the primary material. and used to produce things like refrigerated veneer and many other household equipment such as stoves and so on.

Review page:

Since the polished sheet does not have the ability, geometric protrusions are generated on the surface of these sheets so objects can easily be placed and moved. This is done because smooth surfaces do not allow that, and objects will undoubtedly slide on them.

The drawing process used to create proper advertises on the sheet steel. Then these sheets are used in production process.

These plates are used in various structures, including emergency stairs, deck and pedestrian bridges, truck floors and vans, among others.

Sheets with different colors

A metal gray color specifies the steel sheet in the default state. As a direct result, the top surface of the steel plate is rarely covered by an electrostatic color coating.

Currently, there are 15 different colors available for steel plates, used in the production of Pavilion, Gabelle, Rooftops, household items and other similar items.

These sheets have low overall weight and high formability. Also, their resistance to moisture and corrosion has significantly improved with the presence of a layer of color.

The production of these sheets starts with the complete removal of any grease or other impurities that may be present on the surface of the sheet. At the next stage, they washed the sheets and completed another preparation before they were ready for color.

When referring to the process of making these plates, the term “electrostatic painting” refers to a stage in which a kind of color (made from epoxy, polyester, polyvinyl chloride or polyurethane) is sprayed on the sheet and then the steel sheet is placed in the furnace.

Galvanized sheet in different colors

Steel business creates various products, including color sheet as one of those things. Creating this color sheet is done in conjunction with the construction of galvanized sheets and provides an additional layer of product protection.

Galvanized coil is introduced in color sheet manufacturing machine by this method and the preparation process will then start. A dehydration solution is used to wash the galvanized sheet, and then a brush is used to clean the surface of the sheet.

This method is implemented twice to ensure that the surface of the galvanized sheet is free of dust and other potential pollutants. In the next step, the sheet will be dried by hot air to prepare.

Now, a certain chemical is sprayed on both sides of the surface, and then the sheet dries again. This is done to increase the corrosion resistance of steel as well as the ability of paint to glue to the surface of steel. This material has the quality of preventing fading or changing colors.