Since raw steel can’t be used in its pure form, steel billets are made in different sizes with various properties and prices.

The operations of the ejection, shaping, and rolling, along with other forms of metal processing, all use steel billets as a raw material or feedstock.

Structures such as bars and poles, as well as other geometrically precise structures, may be fabricated using this material. When it comes to manufacturing parts and components for engineering and machining, forges and machine shops are common places to look.

Steel that has just been produced but is still in the shape of a square or metal bar is referred to as steel billet. Billets must be framed into more useful shapes and sizes in order to be functional.

The Isfahan iron foundry is the first and biggest manufacturer of building steel in Iran. It also serves as the center of the Iranian steel industry.

In the year 1350, the Isfahan Iron Foundry was created. This manufacturing facility was established in the southwestern part of the Isfahan province, near the city of Zarin Shahr. More than 23 countries in Asia, Africa, and Europe are now receiving items that were manufactured at the Isfahan Iron Smelting Factory.

The I and H beams, flat and ribbed bars, corners, studs, and logs are the most common goods that come out of this facility.

The output of this manufacturing operation has been put to use in significant construction endeavors including the Milad Tower, the Tehran subway, and many other areas.

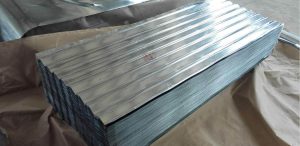

Steel billets

Steel billets are the product that results from the second step of the manufacturing process for steel bars when sand that was provided is used. For things made of steel to be put on the market, the steel itself must first be processed and cut into ever-smaller pieces that can be used more quickly.

It is necessary to first cast the crude steel into the desired shape before it can be used. Before being put to use, steel billets, which have not yet been formed into the desired shape and are instead in the form of metal bars or squares, must first be cast.

The term “steel billet” refers to newly manufactured steel that has not yet been shaped into a square or any other shape and is still in the form of a metal bar.

The steel bars have a flat surface and are rounded in shape, with widths ranging from 6 to 50 millimeters. These bars are made in extremely long lengths, and once they are in your hands, you may quickly cut and cleanly twist them without any harm.

When they have been molded and scaled into more useful shapes, only then, can they be used in ways that make sense to the average person? After they have been shaped, they are either sent to other tool shops or put to some other kind of use.

Unformed billets are used to store money and are also used in the striking process, which produces coins and gold bars. Steel billets are known for their pliability and suppleness, which are both shown when they are exposed to variations in temperature during the operations of shaping, molding, and forming.

Steel bloom sizes

There is no prescribed minimum size for a steel bloom; nevertheless, a billet may have any cross-sectional area between 38 mm and the size of a bloom that is smaller than the cross-section of a bloom.

Blooms were slag-filled iron castings that were poured into a bloomery before being transformed into wrought iron during the era when commercial wrought iron was produced.

Blooms are pieces of steel that were produced during the period of commercial steel production. They were created from a first pass of rolling (in a blooming mill) that reduced the ingots’ cross-sectional area to a smaller size, but the blooms were still larger than 36 inches square (230 centimeters square) (230 cm2).

In most cases, further processing is performed on blooms using rotary piercing, structural form rolling, and profile rolling. Final goods such as structural forms, rails, rods, and seamless pipes are examples of common end products.

Items that are continuously cast, including such blooms and billets, retain their qualities after they have been cast. These products are very long-lasting and available in a broad range of sizes, both of which make them suitable for use as feed material in a wide variety of different sectors.

It is not unheard of for blooms and billets to be manufactured to order in terms of their dimensions and the materials that make them up.

Steel billet grades

Applications that need structural support often make use of GR460 grade structural billet steel. BS4449 specifies GR460 as a material grade and designation.

The BS4449 standard for carbon steel bars for concrete reinforcement is a British standard that is used to make things stronger. Because the GR460 grade of steel has a lesser tensile strength than the A615-75 grade of steel, it is not used as often.

The minimum required value for the tensile strength of GR460 Grade Steels is 460 Newtons per millimeter squared (N/mm2) (MPa). It has not been established how much yield strength there is. It is necessary to have thicknesses that are lower than 12 percent for elongation.

The grade A615-75 structure billet steel is used in a variety of structural applications. The “A615-75” material grade and designation are the ones that are specified by the ASTM A615 standard.

Reinforcing Concrete Using Both Deformed and Plain Billet Steel Bars the ASTM A615 standard is recognized throughout the world. The tensile strength of grade A615-60 steel is lower than that of grade A615-75 steel. The tensile strength of A615-75 Grade Steels is measured in N/mm2 and has to be at least 689 N/mm2 to meet the requirements (MPa).

The minimum yield strength that it has is 517 N/mm2 (MPa). The elongation range is at least 6 percent thicker than the minimum thickness.

There are two grades of steel that are both referred to as A615-60: structural billet steel and non-structural billet steel. By the requirements of the ASTM A615 standard, the A615-60 grade is a particular material identity and grade.

The usage of deformed and plain billet steel bars manufactured to ASTM A615 standards in concrete may be beneficial for applications requiring reinforcement. When compared to A615-40 steel, the tensile strength of A615-60 steel is much higher.

Steel billet price

Steel billet prices are influenced by a wide variety of elements, including the manufacturer’s brand, the commodity’s current value on the global market, and the raw materials that are included in the product.

The items, such as scrap iron and iron ore, that are utilized in the manufacture of steel are one of the most significant elements that determine the price of steel billet.

Now, shifts in the costs of iron ore and scrap iron, as well as shifts in the prices of the nations that offer these resources, have a direct impact on the price of steel if they bring about a change in the process of providing steel. For instance, during this week the price of steel billets at one of the ports in the UAE is now trading at a rate of $470 a tonne.

This indicates that during the following few days, there will be a $20-30 rise in the price of Iranian steel billets. In addition to the items that are utilized in the manufacturing of steel, there is one more product, namely coal, that affects the price of steel.

Recently, the price of steel goods such as round bars and steel billets has increased because of the rising cost of coal. When it comes to establishing the cost of steel goods in Iran, the Khuzestan Steelworks is the primary factor that is considered.

On the steel market, the plant will announce the price of steel ingots, and this price will serve as the benchmark for the pricing.

Prices of steel billets are publicized in Iran according to one of three categories: The cost of export ticket ingots in Iran makes up the first category on the list.

The price of iron ingots that are being offered on the exchange makes up the second group, and the price of steel ingots that are being sold on the open market in Iran makes up the third category.

Billet steel properties

There is a distinct difference in the grain structure of billets. Because of this property, it is no longer possible to extract the metal from the process.

Steel billets have a well-deserved reputation for being highly flexible and elastic, particularly when subjected to fluctuating temperatures during the process of shaping and molding.

Steel billets have a set of qualities that differentiate them apart from steel bars and other completed products. These features make steel billets unique.

There is nothing else quite like the grain structure of a bullet. Because of this, the metal may be processed in a manner that is entirely distinct from the rest of the operation.

It is not possible to make use of billets until they have been shaped and sized into more practical shapes. However, despite having been heated in steel furnaces, they still require several molding and shaping procedures before they can be sold or used in a variety of applications.

These operations include milling and cutting, as well as cold and hot processes.

Despite this, the unformed billets have the potential to be used in the manufacturing of coinage and as reserves in the same manner as gold bars are. Before they are shaped into more useful shapes and sizes, billets are not very useful. Before these things can be used for different things, they must go through a series of steps in the manufacturing process.

From unshaped billets, coins can be made, and gold bars, which are similar to gold bars, can be used as reserves. In the end product mix, wire, and bar stock are also used. Centrifugal casting can also be used to make short, round tubes called billets. This is usually done to get a precise metallurgical structure.

Steel billets for sale

Steel billet sale and export have their steps and rules, the first step is to receive the buyer’s order, and after agreeing on the price, they record the order. After paying the requested amount, the factory is responsible for packing the product and then packaging the product.

send the package by sea, air, or land. Then, billet steel ingot exporters are responsible for obtaining all necessary permits for the organization such as mining organizations, l commercial organizations, and other organizations involved in exporting.

After doing all these steps, the team exporting the product should agree with a shipping company and insure its product. After completing these stages, only the export of the goods remains, which is the last step, and they will start the loading of the product.

Nowadays, buying a high-quality steel ingot is a major concern for buyers of this product, because they need to buy a quality product relative to the price of the billet steel ingot.

Fortunately, Iran has achieved many successes in steel production in recent years and has achieved a good place in the world. Iran’s steel record is around 21 million tons, which is a very good record.

The steel industry in Iran is currently the second most important industry in the world, responsible for the largest trade volume. In Asia, there are steel giants like China, which produces about 42% of the world’s steel, and Iran is competing with these promises.

You can purchase steel billets of high quality from reputable vendors through our company who guarantee that the finished product will be of the highest standard. These goods are constructed to withstand the passage of time and are designed to be durable.

Steel billets come in a variety of lengths and sizes, making them appropriate for a large number of applications.

Steel billets are bars or rectangles made from steel that is manufactured for scrap metal trading. After that, these items are put to work to fulfill the requirements that were originally outlined.