PVC Coated Tape Connectors, Galvanized Wire Connectors and Stainless Steel Wire Connectors are all available, and 1,000 unique pieces are available per package. If your goal is to contact us, we would be happy to help.

The improvement in our lifestyles all over the world, in no way, owes to the service of stainless steel that we did when combined with modern technology.

What percentage of the global economy is the stainless steel industry, and how big is it?

During the International Stainless Steel Conference held by Bulletin Metal in November 1984, Paul Rodel of Carpenter Technology Corporation answered this question by providing answers.

In a good year, consumption is expected to reach 5 million tons, except countries that make up the Eastern Bloc.

The global stainless steel industry is estimated to be worth around $10 billion if the average value of stainless steel is around $2,000 per ton.

However, the real value of stainless steel to society cannot be determined by the amount of steel consumed as per ton or dollar.

In retrospect, we can understand other important factors such as the expansion of its industrial base and the development of its technological potential.

Since its weak start in the 1920s, the stainless steel industry has been known as a cutting sector, with high technology. This perception dates back to the early days of the industry.

On the other hand, with the overall development of technology and scientific advances over the last few decades, the development of stainless steel is driven by market needs.

Development of new stainless materials with unique combinations of corrosion resistance, machinability, hardness and other special properties was essential in order to meet market needs rather than satisfy the needs of scientists and engineers.

For example, stainless steel was used for both the Moon’s exit and return journey by human on the Apollo mission.

Moreover, the demand on quality of stainless steel has a major effect on the evolution of material. In order to satisfy the requirements of some vital market applications, new levels of metal performance and reduced error tolerances are required.

For this reason, new production methods have been developed and are required for making high performance steels.

Cost management has traditionally been a top priority, leading to the evolution of manufacturing processes that have more production over time.

The decarboargon-oxygen method (A.O.D.) was an affordable innovation that greatly reduced the costs associated with the production of stainless steel.

Performance and cost improvement are also significantly affected by continuous casting.

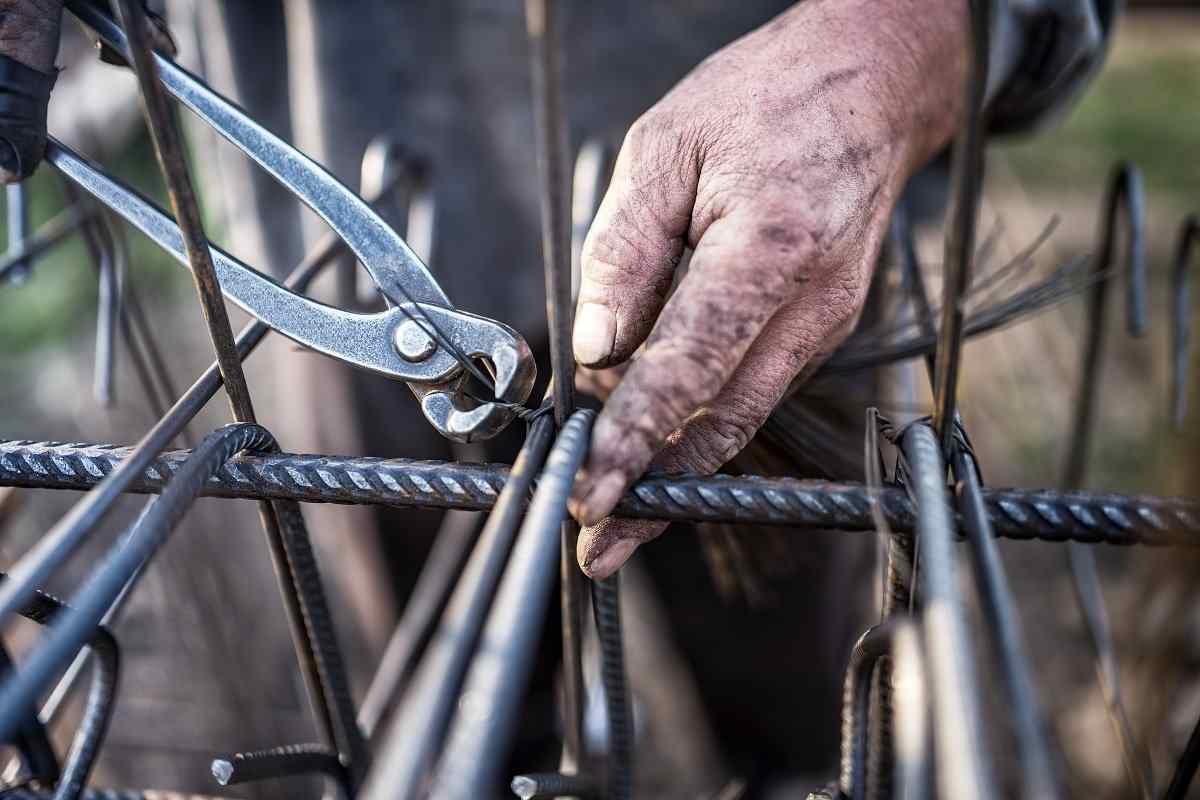

Stainless steel rebar tie wire

Most flexible and low-carbon versions of the annealed steel wire are used to produce rebar tie wire, which is also known as tape clamping wire. This method is primarily used to close and assemble the stainless steel reinforcement bar as well as for the garden backing plants.

It is fully galvanized and has PVC coating on the surface. These features provide flexibility and corrosion resistance.

The components attached to wire ring construction are: copper wire, galvanized wire, PVC coated wire, stainless steel wire, and annealed wire of the highest grade.

The machine that creates the loop nodes, automatically deliver a wire and a straight when it is operational. The ends of the wire were cut and bent in place. The exact length, minimum error rate and cut are highly ordered.

Features of Tie Wire For Bar

Excellent consistency and softness as well. This process has exceptional flexibility and uniformity due to stretching, acid washing and annealing.

Anti-corrosion and tolerance. This kind of soft annealing connection wire can withstand corrosion thanks to galvanized coating and PVC on the wire surface. It is not easy to suffer.

Excellence in quality and standard. has ideal properties and using them will make you more responsible without causing any harm.

Examples of use for tie wire for strip

Mainly used to support plants in the garden, especially trees, grapes and hair.

In daily life, such as food packaging, such as grain, potatoes, lime, sugar cane, seed, and bread, etc.

Steel reinforcement, the repair of concrete structures, and even the rehabilitation of swimming pools have many applications for rebar joint.

Application is recommended for items such as wire, tape, wood, PVC tube and tube, as well as other packaged products.

Handmade handicrafts.

The use of the connection wire made of stainless steel in connection with rebar has many advantages, some of which are listed below.

Due to high corrosion resistance, especially chlorine ion, it is suitable for use in the construction of water bridges.

Reduces the amount of concrete cover to a significant amount, which results in saving time, weight, money and labor.

There’s no need for a sealant like silicon.

The lifespan is significantly improved while simultaneously reducing the amount of maintenance required

In the end, metal can be recycled.

Smart Metal Industry Co., Ltd. was founded in 2016, but our history can be as of 2008. Smart craftsmen have three production workshops in Hebei province, China.

The workshops include technologies like bending, stamping, welding, cooling, and rolling disciplines among other processes.

Is it possible to use the connection wire made of stainless steel with regular strip?

This is because the quantity of stainless steel in the tie wire is very minute. The construction strength is not compromised by corrosion, as the sole purpose of the connection wire is to install the rebar before the concrete.

However, the price of stainless steel wire connection can be up to six times higher than the price of normal connection wire.

It is very unlikely that you would like to use it, especially if you are concerned about the possibility of rust to the surface of the concrete if it is too close to the surface.

One question that is connected to this one is whether it is suitable to use the natural connection wire made of carbon steel with stainless steel bar.

Due to its non-magnetic quality, stainless steel bar is often used in highly corrosive settings, such as coastal building.

It is also used in magnetic resonance imaging (MRI) and research facilities. Corrosion of coronary wires does not affect the integrity of the building, however it can be an aesthetic problem and raise questions about the quality of concrete work.

But more importantly, if there is a problem with the structure’s magnetic signature, the tie wire must always be made of stainless steel.

When working with stainless steel reinforcement, it is important to use the tie wire made of stainless steel, especially when the stainless steel bars for transportation.

If that doesn’t happen, the galvanic operation of carbon steel binding wire will cause corrosion, and the handles will be separated.