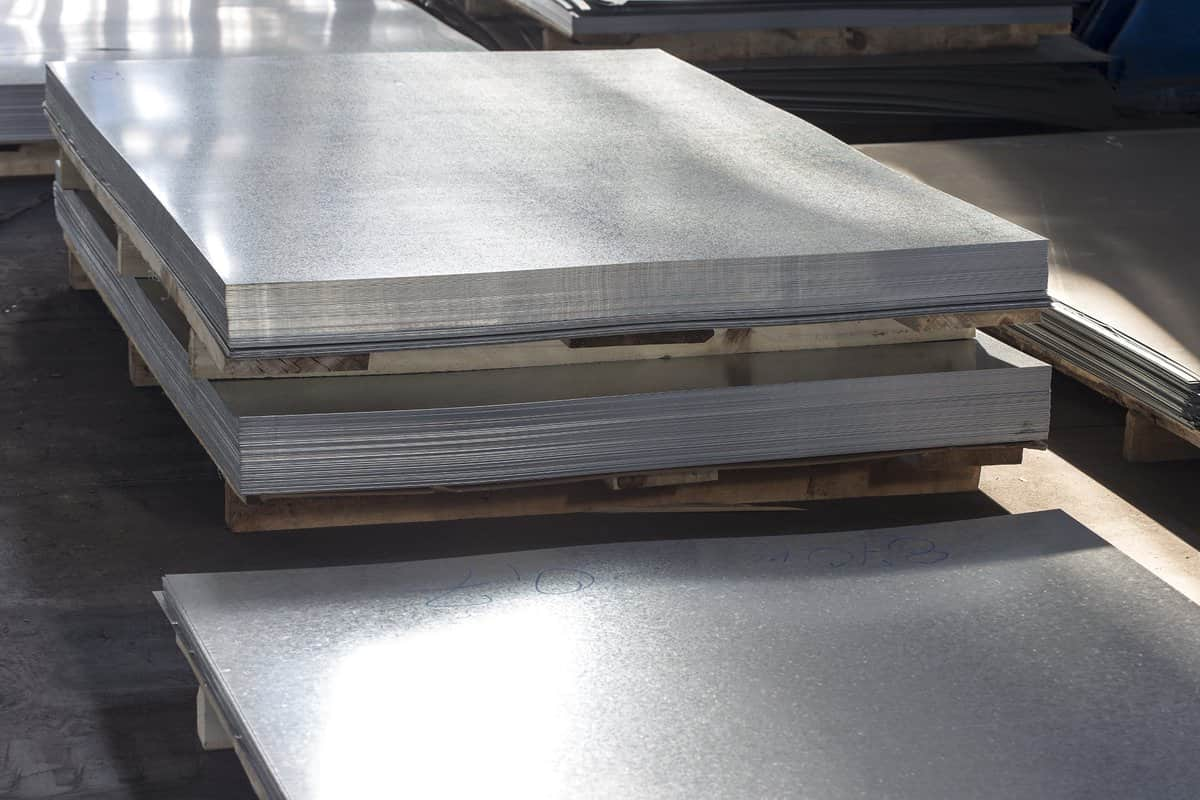

Crystals on the surface of a galvanized steel sheet are known as spline, and are an attractive visual element. The wave pattern can be identified as a snowflake or a star with six rays.

When certain alloying elements are either introduced to the liquid or present as impurities, this is the result of the steel plate. It can also be created when certain impurities are present.

Zinc has been affected by both corrosion resistance and mechanical properties by grain size and orientation of zinc. This can be achieved by alloying matter with elements such as:

The Antimony Bismoth Tin Spangules aluminum cover structure presents a decorative look defined by the orientation of the Zinc crystals and the distribution of the alloying elements in the coating. The spine can be made of lead, aluminum, antimony and tin.

Spangle description of corrosion

Spangle is produced when temperatures below the point at which the zinc may be melted are applied to the zinc liquid which is connected to the steel surface.

In molten zinc coatings, the zinc atoms, which are dispersed irregularly when matter is in liquid form, begin to reorganize themselves in a regular pattern in random locations.

Freezing or crystallization refers to a process in which atoms in a liquid state become a more ordered pattern after they are placed in a disordered state.

The grains are the name of the series for these discrete zones of solidification that occur in the melted zinc. Grain growth occurs as individual atoms on the molten join in a regular sequence to the grains that are being hardened.

The atomistic components of self-organizing of the expanding solid grain into characteristic hexagonal symmetry finished at the diffusion angle. This symmetry is often observable. Once the cover is fully hardened, the individual spreads that have been developed represent grains on the individual.

Dendritic growth is a distinct solidification process, which is similar to the formation of spinons in galvanized steel sheets. The couples formed as a result of this process are in the form of snowflakes.

spangle size can be affected by the following factors:

Zinc-included chemistry

cooling rate

no roughness in bed

impurities

alloying element

The regular rotation angle, at least and zero, are three different types of spinangle sizes that can be found on galvanized steel sheets.

When compared to a surface that is uniformly made of zinc-iron alloy, a surface that has spines has worse properties than both corrosion and mechanical resistance.

Sheets covered by different angles can be used for different worldly purposes. On the other hand, splats should be avoided wherever painting is involved or whenever the application of the outer layer of artificial plastic is necessary for completion or decoration.

Steel Decorated with Star

The name given to a pattern seen on galvanized steel from time to time is spangle. Spray coatings were once common in almost all hot-dipped galvanized steel products.

The term “sprinkling water” refers to a steel pattern that forms a snowflake or a star with six lobes. This pattern was observed by the naked eye and can be examined in more detail by a 10-fold magnification factor.

Due to the changes made to the hot dip galvanization process, this is not common to it that it was before, but it still occurs sometimes.

Snowflakes and stars that are sprayed in steel are perfectly symmetrical in all directions. They radiate from one center in all six possible directions along what is known as a dendritic. Teeth are like stalks; They have smaller branches that sprout like leaves.

When molten zinc coating on galvanized steel begins to cool under the melting point of zinc, which is 787 degrees Fahrenheit (419 degrees Celsius).

Individual atoms on the molten run according to Brownian laws of motion, which can be assumed to be more random or less random. When zinc reaches a temperature slightly lower than its melting point, zinc atoms that are closer to steel begin to adjust themselves in regular patterns.

A number of zinc atoms make chemical bonds with iron to produce an alloy. The very thin layer of zinc that is directly above this alloy begins to develop what is known as the “seed”.

You’ve most likely observed comparable seed shapes in other types of materials, such as sandstone grains that are embedded in a sandstone bed, for example.

Although zinc grains that adhere to the surface of galvanized steel are considerably smaller than sandstone grains that are found in a rock piece, they are kept together by much stronger atomic forces.

The steel surface is covered by a pattern of single atoms on the surface that binds itself to a zinc seed, where it becomes hard. Zinc atoms tend to be grouped in grains that have hexagonal symmetry because there are electrostatic forces between them.

Nucleation is a process in which grains grow on the surface of galvanized steel as pure steel. This occurs when the steel is cooled.

When galvanized steel (remember, the freezing point is on 787 degrees Fahrenheit!), the core process should occur quickly, resulting in smaller grains. Larger grains form in galvanized steel when the material allows to cool down at less speed.

Why Visible Spangling Now Less Common Than Past

Customers had previously assumed that the steel was not actually galvanized if it could not see the turning angle, as it often happens. However, there used to be a impurity on the melt used in the heating process, which is why almost all of the galvanized steel was sprayed.

Lead atoms in Zinc-coated ore were formed around unmelted lead atoms, which consisted of granular crystals on the steel. Galvanized materials have found techniques for creating lead-free from molten zinc in reducing environmental impacts and health hazards as evidence of health issues.

It seems that getting rid of lead will make the steel more durable. When steel is used in hot and humid conditions, a phenomenon called delayed adhesion and zinc grinding can produce even from 100 parts per million lead in galvanized blends.

Zinc purification was performed by galvanized methods. The majority of spingling was also eliminated, while the lead was eliminated. Galvanized steel today has a smooth and bright surface.