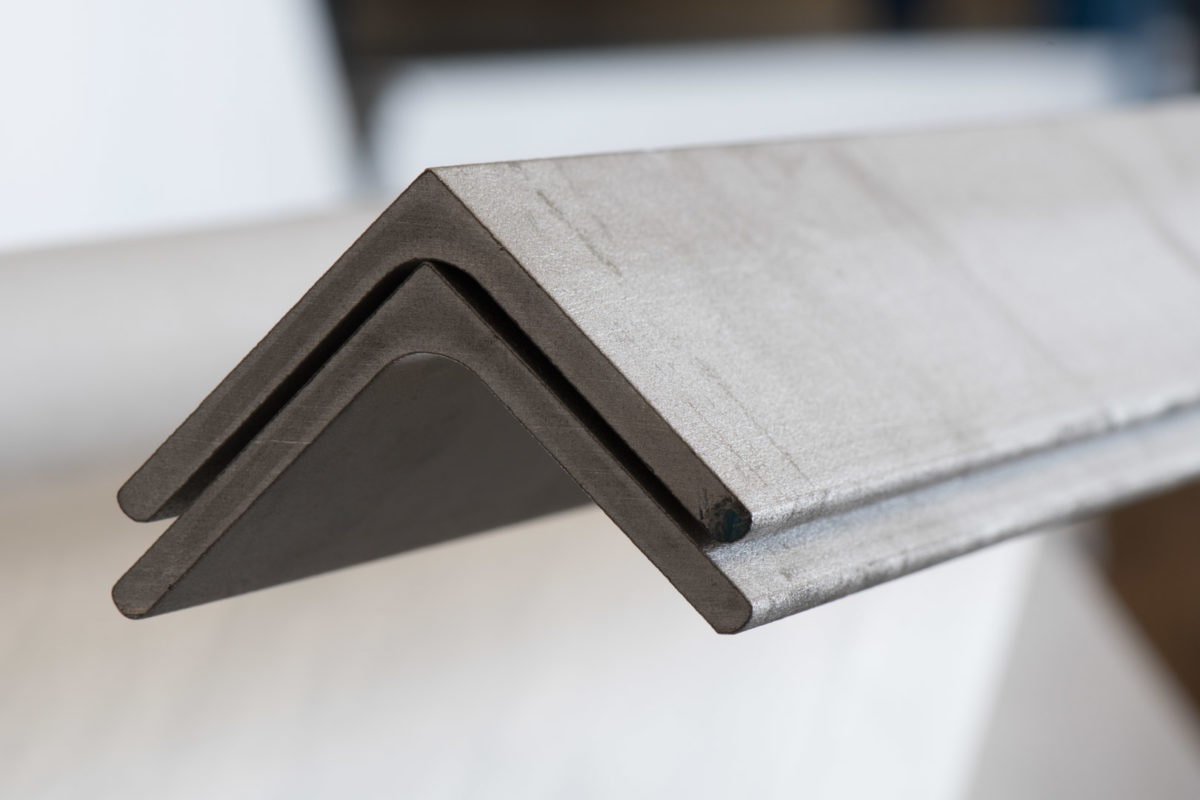

Angle iron steel, also known as steel angle or steel angle, is basically made of hot-rolled carbon steel or low-alloy steel with high strength. This model has an L-shaped cross section with two legs equal to or equal to the angle of 90 degrees.

Structural angles are available in different sizes that fit your application. Custom sizes are also available. Angle steel you can offer? Angle steel as a popular structural material, is widely used in bridge construction, construction and engineering.

Angle steel can be divided into low carbon angle steel and HSLA angle steel according to the steel content. Low carbon steel angles include A۳۶, S۲۳۵JR, q۲۳۵, SS۴۰۰, SS۴۹۰ and ST۳۷.

HSLA carbon steel angles include A۵۷۲ and A۵۸۸. According to surface treatment, angle steel is divided into three types: black (no treatment), hot galvanizing and painting.

Various applications of angle steel: support and structural factors – bridges, warehouses, shelves, cable towers, power towers, telecommunications towers, equipment and so on. Daily use – flat frame, chair, bench, railing bases, air conditioner brackets, coffee tables, etc.

Find soft iron manufacturers and soft iron suppliers from the list of IQS. Refine your search below to find soft iron manufacturers and suppliers based on location, company type and certificate. Send your request using RFQ tool with all steel companies of your choice.

The advantages of using angle iron for angle iron, you can also choose other options such as traditional C channels or bracket.

Here are three reasons for providing quality and performance compared to other types of channels: High power-to-weight ratio is one of the problems with other types of channels that they are weak. Not with angle irons.

Basically, the high carbon hot-rolled process produces a quality product that is much stronger than competition. It can be used for anything from rails to structural foundations. The grain structure becomes stronger during the production of the iron angle, grain structure of the metal.

This is done by metal cutting, heating the pieces, spinning them larger then heating and rolling them again. This would create a channel with the power of about 80,000 PSI and the performance strength of about 50,000 PSI. Advanced iron angle roller forming technology is a complex process.

Computers and other technologies can make the process easier. Computer-controlled furnaces can heat metals up to much higher temperatures. Multiple rolling sessions to prepare metal for additional testing in the future.

laser cut metal with very precision, turning raw metal into the best angle of iron strength. You will see these benefits and more when you use angular-shaped iron products.

The process of producing iron angle is a process of producing a variety of manufacturing processes, but the roll forming is the simplest and produces a high quality and uniform product.

The rolling mill is a machine with a long series of rolls. These rollers can convert metal bars into angle iron bars. The process starts with metal storage. The metal is injected into the first roll that holds the metal tightly. Each set of subsequent rollers is placed to slightly change the shape of the metal.

As the metal bar moves in the machine, rollers bend the bar along a linear axis, press the bar and make it up. When the metal reaches the last roller, it has become a new angle iron.

Then it can be opened, cut, and prepared for transportation. They may be clamps that cause holes or defects in the metal. The punch head is often used to form angular iron.

In the roll forming process, by increasing the stability of product structure, small wastes are produced, and can be used to create angle iron and many other metal shapes with nearly size and shape. Application Iron Angle Iron can be drilled with holes or shapes to allow hardware connections.

There is a direct relationship between the size of the cast iron and the load capacity. The larger the angle of iron, the greater its capacity. Angular metals can withstand heavy loads indefinitely.

They are used for the construction of rebar, drawer slides, sport floor systems, guitars, gypsum, control joints, and expanded joints. Construction, aerospace, automotive, railway, furniture, air conditioning, hardware and storage operations all use the angle of iron.

Iron, steel, brass and aluminum are material used for iron angle. Iron and iron steel angle instruments are common, but brass and aluminum are also used to make angle iron.

For example, brass is used as a light-bearing element when the element is very visible. And Iron Angle is one of the most well-known types of structural steel with unique L-shaped profile that can be used in hundreds or thousands of different projects from custom flat frames to ladders, furniture or cart frames.

It’s versatile. It’s both affordable and easy to use, and with enough practice and planning, it can be used to build anything. Here are some of the advantages that Iron Angle can offer for your next project: #1 Affordable Iron is a strong and lightweight product.

Its strength and durability are relatively economical compared to other types of materials, such as other structural steel products, other metals, wood or composite materials that are comparable in strength to that of iron angle.

This advantage is that it is a cost-effective alternative to many expensive metals such as aluminum and competitive with wood and some composite materials.

2 A wide range of the use of angle iron can be used for different purposes, from making frames for lathe or cowing machines to add support for heavy trailers. It can be used as a structural part, such as a joystick on a light roof or as a frame for a door, or it can be used as a part of fame or as support for heavier structural elements.

It can also be used for purely decorative purposes, such as window frames or art projects. This method is relatively hard and can be easily formed with a gear, easily cut with a torch, wheel or saw and bent with a clamp or other appropriate tool.

Even with cheaper MIG machines, welding is easy and complex structures are easily formed for large projects. It is also possible to drill and twist angular connections together, but much better welding.

Conclusion

We are eager to do what we do and strive to meet the needs of our customers by providing quality products and services. And don’t hesitate to question any questions our support teams are available. For more information please visit our site.