Many buildings use steel bars. For example, rebar in concrete is used as a mesh for providing strength.

In reinforced concrete structures and masonry structures, rebar known as reinforcement steel and reinforcing steel is one of the steel bars or steel wire mesh used to reinforce and maintain concrete in the stress.

Other names for steel rebar are reinforcing steel and reinforcing steel. The surface of the rebar is often designed to improve the quality of the bond it has to the concrete.

In order to compensate for the fact that the concrete is strong when pressed, but when drawn is relatively weak, the use of the rebar is needed.

The capacity of concrete to carry tensile loads and consequently, the overall strength of structure can be increased by placing reinforced bars inside the material.

Various rebar applications include:

Primary resistant is the term used to refer to the use of reinforcement used to create resistance to design loads.

Secondary amplification is used for items such as durability and aesthetics by providing local resistance to limit cracking and temperature-induced stress. This can help you to avoid breaking the matter immediately.

Be resistant to centralized loads, so distribute the effect of such loads to a larger area.

Keeping the other steel bars in the right place allows them to better bear their loads.

The connection rods made of foreign steel are used to reinforce and strengthen the masonry structures, and are sometimes used as a method of preserving the building.

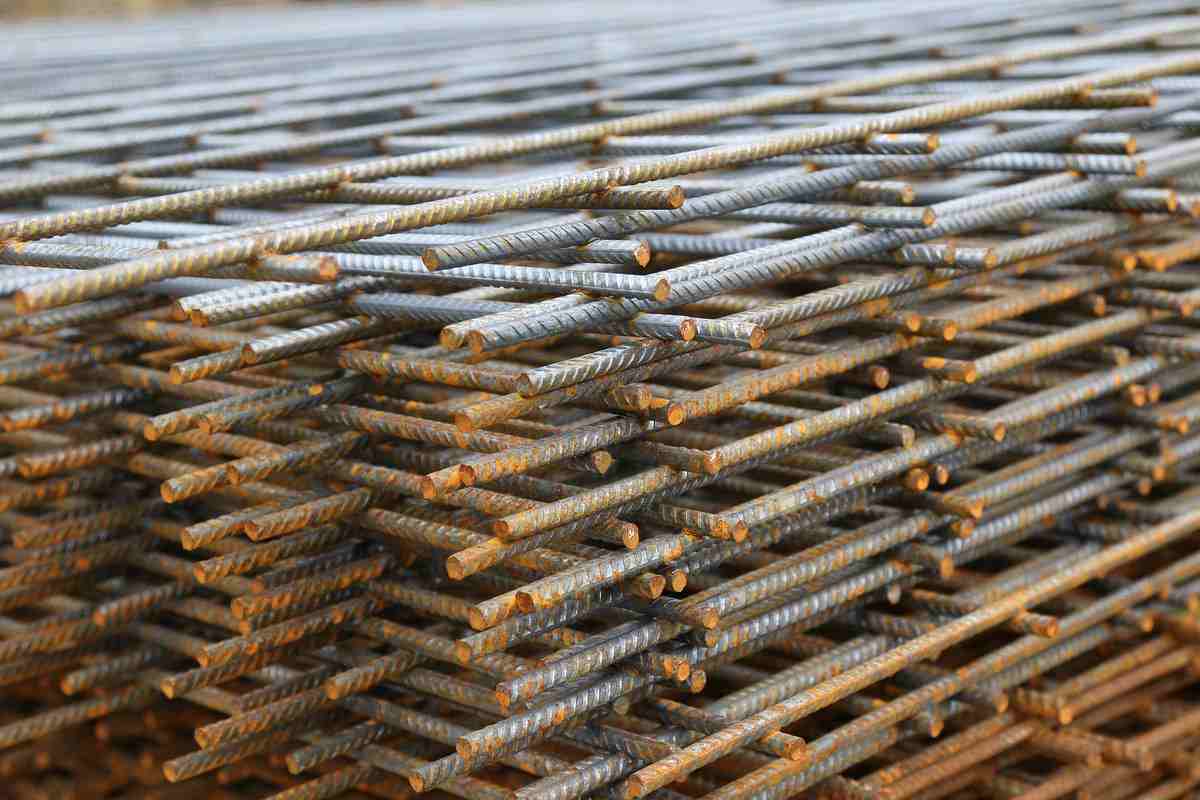

Reinforced masonry materials have numerous X-shaped bars in which they have diagonal stripes which can carry tensile loads. Some of the building blocks and bricks carry these holes. The grier is used to keep the ribar where it belongs.

BS 4449:2005 is a document that sets standards for the tape specification. Steel is used to strengthen concrete. Reinforcing steel that can be welded. Product available on tape, coil and decoding form.

When producing rebar, high-yield or average class 250 or 250 N/mm۲ characteristic of tensile strength is usually used in the production process.

Both categories contain about 99% of iron as the primary component, with lower quantities of manganese, carbon, phosphorus and sulfur. The percentage of carbon in steel determines both the quality and the degree of steel.

Carbon can be found in conventional cold-rolled steel about 0.25%, while high-performance hot-rolled steel includes almost 0.40% carbon.

Bars can be created in various forms, including:

Round.

Complicated.

Tilted.

Long, twisted, and pretentious.

Twisted and coiled.

Following the BS 4483 directive, known as “Steel Fabric for Concrete Reinforcement”, several forms of steel reinforcing mesh or fabric can be produced. Specification.

Typical dimensions of sheet are 4.8 m in length and 2.4 m in width. To withstand regular use, this is produced by connecting the wire or electronic welding to each other.

It can be produced in a variety of different methods, depending on the desired use:

The square grid has a mesh size of 200 mm/200 mm and a weight range of 1.54 to 6.16 kg/m2. Normally used for building floor laboratories.

The weight range for rectangular mesh is 3.05-10.9 kg/sqm, and mesh size is 200 mm x 100 mm. Normally used for building floor laboratories

The long mesh has a mesh size of 100mm/400mm and weighs 2.61-6.72kg/m2. “Road and road construction has its regular usage.

The packing mesh has a mesh size of 100 mm in 100 mm. It is typically used in laboratories supported or suspended by the ground.

steel rebar building

Steel rebar is used in many parts of the building to provide strength to many building parts. When you try to plan and buy materials for a cement or concrete construction project, you may hear the term “rebar” around.

This is because the Rebar is usually used in these types of projects. What exactly is the rebar, though? In particular, how does the foundation contribute to your overall project, which makes it so necessary?

The use of concrete often requires the use of rebar, a type of steel bar. Concrete mixture could be created by adding the steel reinforcement to the concrete mixture.

Using RIBAR in your construction projects, whether it’s floor layers, walls or posts, prevents cracks from spreading throughout the structure and eventually fails it.

However, concrete, rebar and other strengthening materials can help adjust where cracks appear and increase the size of them. In addition, it will increase the structural strength.

What makes this vital component of my project re-open?

reinforced concrete with rebar is three to five times more resistant to cracking. This is done using a reinforcing bar that is corrosion-resistant in order to provide tensile strength.

If you want to add the structure to your concrete, use the tape as your support system significantly more effectively than using steel wire, fiberglass reinforcement or any of the many other solutions that are already on the market.

Why? Because this leads to structural integrity.

There are several different types of tape.

In the market, there are different types of rebar, including:

The use of carbon steel rebar is essential for the construction industry. The vast majority of these concrete structures have called for its implementation. Why? While offering a very good power, this option is more cost-effective than other options.

More common rebar can be replaced by GFRP, which stands for Polymer Reinforced with Glass Fiber. The rebar, which acts as a reinforcing agent, is made in the form of wood using fiberglass. Tensile strength is another measure of its good comparison.

In order to prevent corrosion, galvanized rebars are often used in construction projects. The zinc was electrically placed on the rebar in several ways.

Electroplating, hot plating and cold plating are all examples of these processes. Zinc acts as an obstacle to prevent any potential damage to the steel.

Since zinc-galvanizing property in corrosion condition makes it unsuitable for use in corrosion conditions, stainless steel bars are used in special cases. Normally with price tag is higher than the galvanized bar. For this reason, the work is done only in very difficult circumstances.

The epoxy coated rebars are an alternative to cutting edge and cost effective for use in corrosive situations. Epoxy is applied to the tape surface to prevent corrosion.

However, in places where with a movable sub-degree, splitter, or mechanical movement that can remove the protective cover and allow the corrosion elements to access the steel, this may not be the best bet.

It is simply said that the rebars sold in European markets are measured using a system different from those used in the United States. They continue to act as a reliable amplifier for the structural concrete you use.