Metal Bullet

Steel billets are semi-finished components used in manufacturing derivatives. The steel product bulletin is available online and can be used to learn about the requirements of metals. Steel billets are raw material or feeding material for a variety of metallurgical processes, such as ejection, shaping, and rolling.

Rods and poles, for example, require a high degree of geometric precision in its production, and this material can be used to make both. When searching the place to make parts for engineering or machining, forging and machinist are two common places for checking.

On the other hand, the oldest and largest manufacturer of Iranian structural steel is also the oldest: Esfahan Cast Iron. It is also the main center of Iranian steel production.

The Isfahan Iron Melting Plant was established in 1350. It is located in the south-western part of the city. More than 23 countries in Asia, Africa and Europe receive exports from Esfahan Steel Smelting Plant.

The most common items made in this facility are: I and H beams, straight and jagged bars, corners, plaster and logs. Key construction projects, such as Milad Tower and Tehran Metro, have benefited from this manufacturer’s products.

In the second step, the rebar is reused in order to make it a rebar and the product is called a steel billet. steel must be refined and cut into the ever smaller bits so that it can be used faster if used in the production of goods for sale. This is when manufactured goods are ready for sale.

Standards of steel bullion

Our steel ingots are made with world-class precision specifications. casting is required to shape raw steel into the desired shape before it is used. Steel billets, which are metal or square bars and have not yet been formed properly, must be poured before using them. This is because the required form of steel spades has not been created.

“Metal billet” refers to the newly made steel, which still has the shape of the metal bar. This steel has not yet been formed in the form of a square or any other geometrical pattern; It still looks like a tape.

Use them in such a way that only after they have been formed and become more practical forms will make sense to the average person. After design, they are sent to various equipment companies or used for other uses.

Shaped ingots are used in storage and shockproof processes of gold coins and bars. Metal ingots are heated in different degrees during forming, forming and molding process and reveal the flexibility of the material and its eroding. The billet steel is widely considered due to its flexibility and high ductility.

Bloom does not require at least 38 cubic millimeters of cross-section, but the size of the blooming plate is all the size, and the cross-section size of Bloom must be. Steel bubbles can be as many as they want.

During the commercial iron production period, the blossoms were filled with stainless steel material that were thrown into a loose garment to become iron. They call flower farms “blossoms”.

Steel patches are small fragments of the broad industrial era of these metals. The cross section of ingots decreased during the first pass of rolling (at a blossomed mill), but the resulting bubbles were still larger than 36 square inches (230 square centimeters) (230 square centimeters).

Most blocks have more processing, such as rotary perforation, rotating structural shape, profile rolling. Structural forms, rails, bars and seamless tubes are examples of common final products. Complete products such as architectural shapes are another example of this.

A melting workshop produces steel billets, which are then used in the mill rolling production line to make steel bars. Steel bars are the final product of this process.

1-This is how it is done:

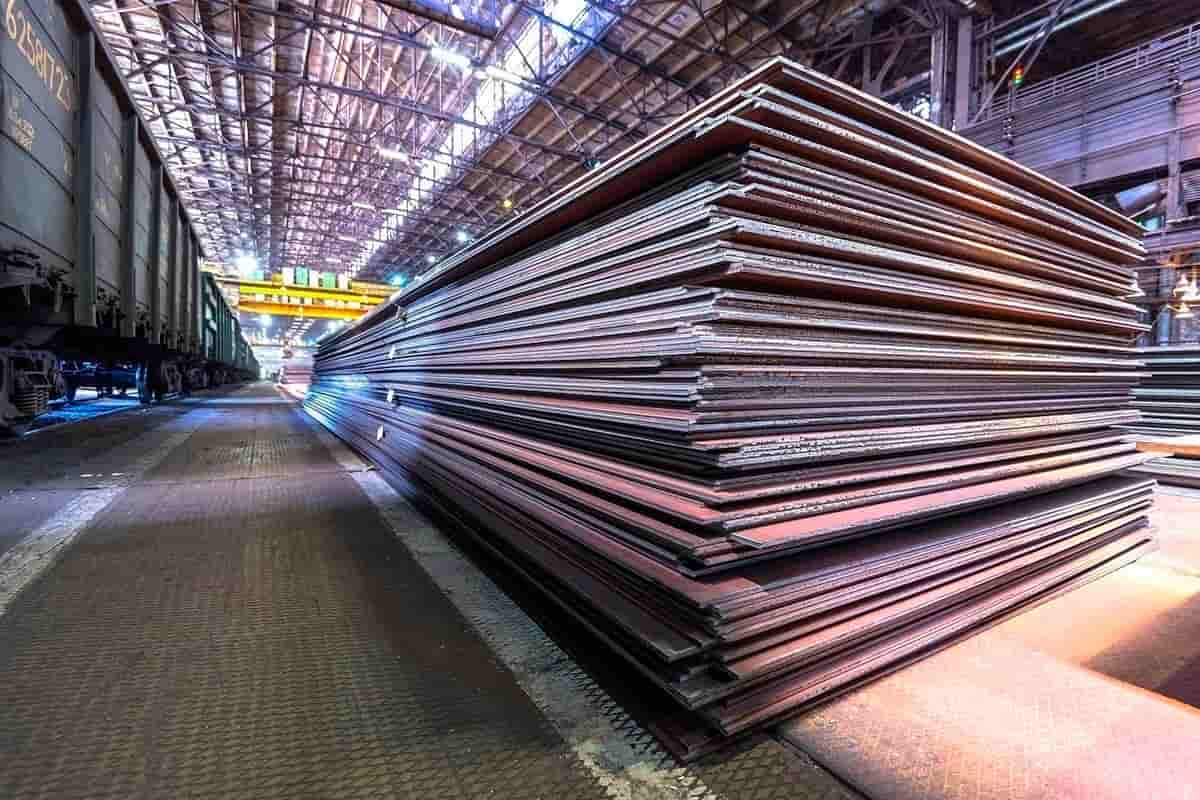

Steel waste is transported to the melting plant and stored in a designated courtyard for this purpose.

2- The waste collected is placed in a large container and heated to melt, but it is not given before a careful study of the properties of the necessary materials and additives. These properties include hardness, toughness and corrosion resistance, among other things, and they differ based on chemical and additive content.

3- The cast steel is placed through a process that leads to the formation of billets, which are approximately 5 cm in size 5 cm.

4- It is then transferred to a rolling shop, which can be placed in a whole other area, and the rolling shop is in the production process.

A: The billets are put in a furnace discharge, and they are discharged at that point into the furnace.

Billets travel in the furnace, where they are heated to a certain temperature to prepare them for rolling.

C – The billets are subsequently transported through the mill train, which consists of vertical and horizontal bases. The platforms are responsible for using the billets as appropriate.

d – Steel which is currently moving at very high speed is transferred to heat to shut down through a nearby carpet rail line.

E- By following thermox, the steel is sent through cutting, where it is cut into the length of the stock, usually 12 meters long.

F – Steel bars are then transferred to the cooling bed to cool down.

G- The final stage is closed and the stack part, where the steel is bundled and stacked before transferring to the storage yard, which may now be sold to the construction sites.

Metal Bullet

A well-known publication in the steel manufacturing industry is a metal bulletin. You can compare these products with the products for this magazine.

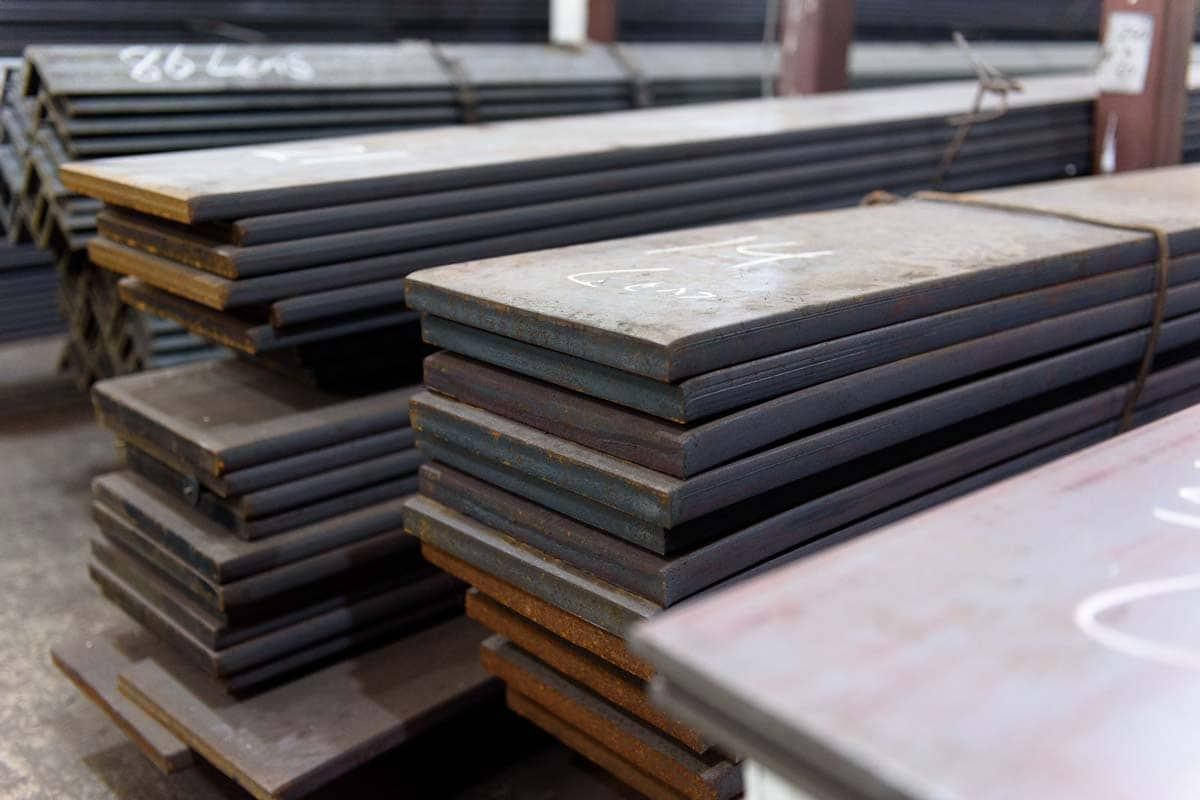

Rectangular steel billets are the most shaped for steel spades. Consistently cast products, such as blossoms and billets, maintain their original quality after casting process.

These products are ideal for use as food in a wide range of sectors due to their durability and the very different sizes they come in.

It is not unusual for a wailing or billets to be constructed with certain specifications, both in size and materials used in their construction.

In many areas that require structural support, GR460 structural billet steel is used. The standard specifies BS4449 GR460 as the material grade and classification.

The UK government set the BS4449 standard for carbon steel bars used in strengthening the concrete to make the material stronger. This is a British norm. The grade of GR460 steel is not used as a grade of A615-75 steel due to its low tensile strength.

Steels specified as GR460 must have tensile strength that is less than 460 N/mm۲ per square millimeter (MPa). Insufficient studies have been done to determine the yield strength of material. The thickness must be less than 12% before the elongation occurs.